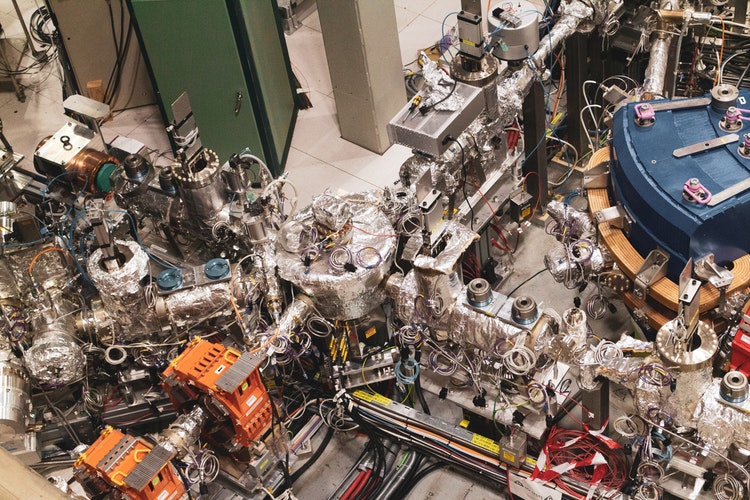

Coordinate measuring machines (CMMs) played a crucial role in bringing automation to the production lines of North American factories. CMM machines can be run by computers to scan parts or objects to detect flaws in them, which make them perfect for automating quality control on production lines.

The rise of the CMM machine came at an especially important time, as after years of global dominance manufacturing in North America was threatened for the first time by competition unleashed by globalization from countries that benefited from cheaper labour and fewer regulations.

CMM machines deliver tangible efficiency for your business, but there are things you can do to make sure they run as effectively, so you can get the maximum benefit.

Only Let True Experts Repair Your Machines

CMM machines are sophisticated and complex, and if your company doesn’t have an in-house metrology expert you need to find one. You can hire metrology experts to calibrate your machine, as well as giving advice on how to find replacement parts. These experts keep up with the latest coordinate measuring equipment news and info to ensure they’re up to date, so you can rely on them when it comes to getting your most important machines up and running.

Only trust your CMM machine’s repair to an expert that has been ISO 9000 and ISO 17025 accredited.

Maintenance from the Beginning, and Throughout

CMM machines are sophisticated and very sensitive. Given that they perform the role of quality control, they must be extremely reliable. Make sure they are installed by a professional metrologist before you use them. Even the room’s temperature can affect the way this equipment performs, so these kind of variables need to be adjusted for before you use it.

During the life of this equipment, maintenance will be needed. When it’s time, consult an authorized CMM machine dealer. They don’t only sell this equipment — they also provide upgrades and retrofits, CMM calibration, machine relocation, portable arm calibration, and preventative maintenance.

Don’t look to independent repairmen — authorized CMM dealers have the experience and the know-how to keep these machines working.

Train Employees to Work alongside the Machines

While they’re often most associated with furthering automation, CMM machines still require humans to operate them under certain circumstances.

Training your employees to work alongside these machines is an important way to get the most from them. Be on the lookout for metrology experts that offer CMM training courses, either through in-class sessions or by e-learning modules.

If you take in-class metrology lessons, you’ll get the benefit of gaining hands-on experience with a variety of real CMM machines. Online lessons give you incomparable convenience and allow you to absorb the lessons at your own pace. They can also be used by employees who have already trained as a refresher course, while E-Learning software also provides an extensive library of software features that workers can brush up on.

CMM machines helped rescue North American manufacturing in its moment of need, and if you apply all these tips your CMM machine will work wonders for your business for years down the road.